VT-441C(G1)

Laminate/Prepreg

UL Approval: E214381 Version: 10/03/2025

/127/128

Storage Condition & Shelf Life

|

|

Prepreg |

Laminate |

|

Storage Condition |

Temperature |

< 23℃ (73℉) |

< 5℃ (41℉) |

Room |

|

Relative Humidity |

< 55% |

/ |

/ |

|

Shelf Life |

3 Months |

6 Months |

24 Months |

- The prepreg exceeding shelf time should be retested.

- Take care in handling thin core laminates as they are easily damaged.

- If the prepreg is not consumed within 48hrs after opening the vacuum package, it is recommended that the bags be resealed.

- Material is available in both long and short grain. The grain direction is indicated on the label with an arrow.

Precautions In Handling

- Please be careful when single ply of 1080 prepreg is designed to the dielectric layer.

- VT-441C(G1) has weaker thermal resistance than regular VT-441. Please be very careful when 8L and higher layer count is designed or dielectric with single ply of 1080.

- VT-441C(G1) Dk is a little higher than VT-441. Please take it into consideration whenever impendence control is required.

- CTI grade-1 only can be guaranteed when the full stack-up is from VT-441C(G1) material.

- Please be noticed that the surface roughness and clearness affect CTI rating.

Prepreg Availability

|

PP Type |

Resin Content |

Press Thickness (mil) |

DK |

DF |

|

@ 1GHz |

@ 2GHz |

@ 5GHz |

@ 10GHz |

@ 1GHz |

@ 2GHz |

@ 5GHz |

@ 10GHz |

|

7628 |

50% |

8.0 |

4.9 |

4.9 |

4.8 |

4.8 |

0.011 |

0.011 |

0.012 |

0.012 |

|

7628 |

46% |

7.5 |

5.0 |

5.0 |

4.9 |

4.9 |

0.010 |

0.010 |

0.011 |

0.011 |

|

2116 |

58% |

5.0 |

4.7 |

4.6 |

4.6 |

4.5 |

0.012 |

0.012 |

0.013 |

0.013 |

|

1080 |

68% |

3.1 |

4.3 |

4.3 |

4.2 |

4.2 |

0.013 |

0.013 |

0.014 |

0.014 |

Remark: More types could be available upon request.

When 2116PP or/and 1080PP is used as the outmost layer, 2-ply minimum is required to ensure CTI GRADE-1.

Laminate Availablity

|

Core Thickness |

Stack-up |

Resin Content |

DK |

DF |

|

mm |

inches |

@ 1GHz |

@ 2GHz |

@ 5GHz |

@ 10GHz |

@ 1GHz |

@ 2GHz |

@ 5GHz |

@ 10GHz |

|

0.20 |

0.008 |

1-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.30 |

0.012 |

2-1506 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.38 |

0.015 |

2-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.41 |

0.016 |

2-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.76 |

0.030 |

4-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

0.91 |

0.036 |

5-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

1.07 |

0.042 |

6-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

1.37 |

0.054 |

7-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

1.45 |

0.057 |

8-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

1.47 |

0.058 |

8-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

|

1.52 |

0.060 |

8-7628 |

46% |

4.6 |

4.6 |

4.5 |

4.5 |

0.011 |

0.011 |

0.012 |

0.012 |

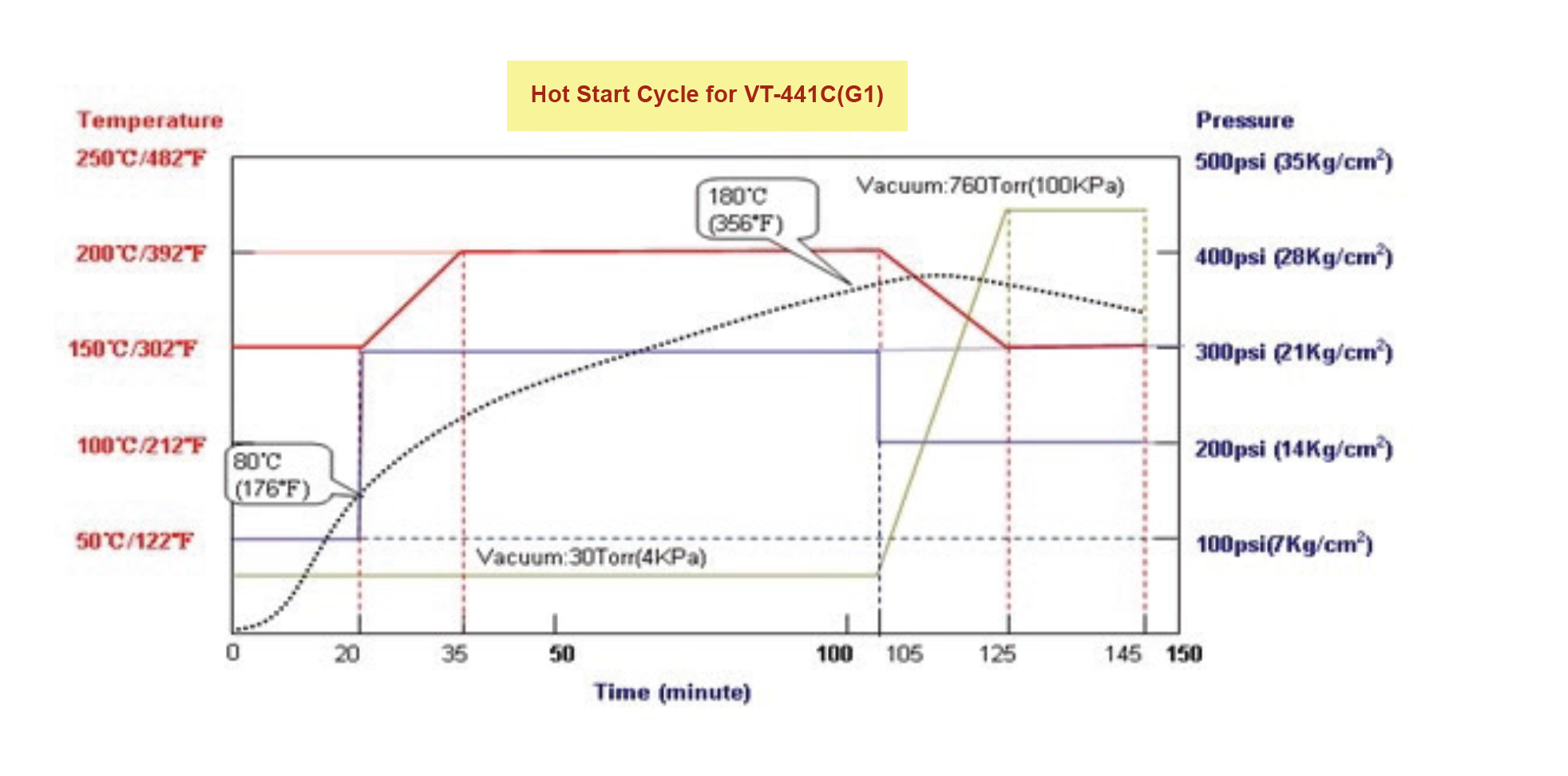

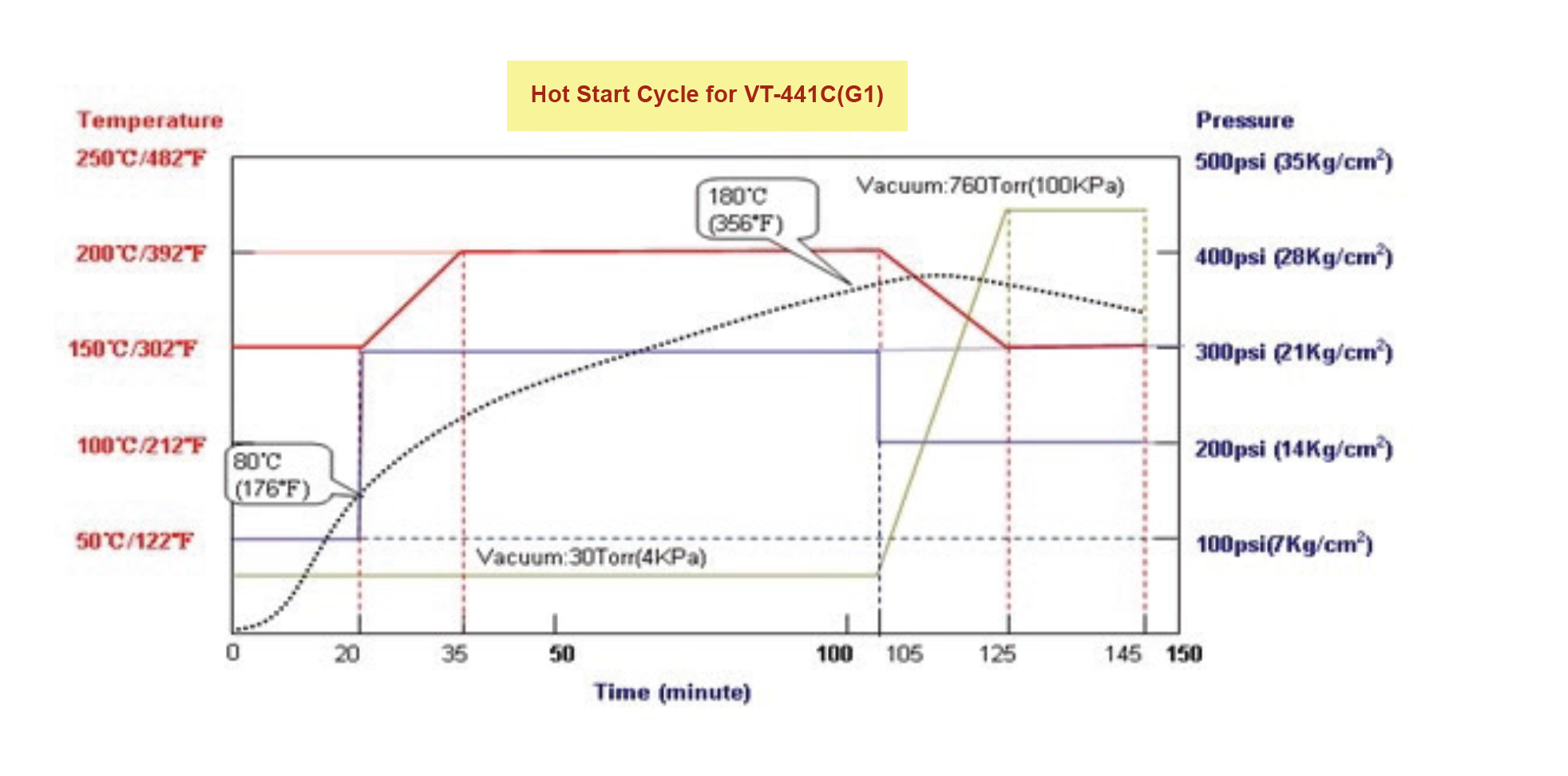

Press Condition

1. Heating rate (Rate of Rise) of material [Material Temperature]: Programmable Press: 1.5~3.0ºC/min

2. Curing Temperature & Time: >60min at more than 180ºC (356ºF) Material temperature

3. Full Pressure: ≥300psi and temperature to apply full pressure before ≤80ºC

4. Vacuuming should be continued until over 140ºC [Material Temperature]

5. Cold Press condition: Keep Plate @ Room Temperature by water; Pressure:100psi; Keep Time: 60minutes

Typical Drilling Conditions

VT-441C(G1) is high fillers system, please adjust drill parameters according to other Middle Tg FR-4. New drill bit, single stack and less hit count is recommended for getting better hole wall quality. Besides, run FA to get optimal drill parameters are necessary.

|

Diameter |

Stack Height |

Spindle (KRPM) |

Infeed (mm/s) |

Retract (mm/s) |

Hit Count |

|

0.25mm |

1 PNL/Stack |

130 |

38 |

300 |

800-1000 |

|

0.30mm |

1 PNL/Stack |

130 |

38 |

300 |

800-1000 |

|

0.60mm |

1 PNL/Stack |

80 |

43 |

300 |

800-1000 |

1. Excessive wear of carbide drill bits. Diamond coated drill bits preferred;

2. For dense holes area or hole size, LE Aluminum sheet and white phenolic entry board are preferred;

Desmearing Process

The de-smearing rate of VT-441C(G1) is less than regular VT-441. 1 time vertical de-smearing is preferred. Please examine hole wall to check de-smearing effect.

Typical de-smearing rate for reference only:

|

1x De-smearing |

Supplier |

Chemical |

|

0.27mg/cm2 |

Atotech |

Alkaline Permanganate |

Punching/Routing

Not suitable for punching process.

Routing process is recommended. Reduce routing speed to prevent edge cracks from outburst mechanical force.

Packaging and baking recommendation

1. It is recommended to bake the board before packaging at 125ºC/4~8h to avoid moisture causing a decrease in heat resistance.

2. If the PCBs needs to be stored for a long time before use, it is recommended to use aluminum foil vacuum packaging.

3. If exceed 3 months after packaging , It is best to bake the PCBs at 125ºC/4~6h before assembly before use.

Downloads for VT-441C(G1)