VT-441V CCL/Laminate VT-441V PP/Prepreg

UL Approval: E214381 Version: 03/12/2024 /127/128/153Storage Condition & Shelf Life

Precautions In Handling

- The prepreg exceeding shelf time should be retested.

- Take care in handling thin core laminates as they are easily damaged.

- If the prepreg is not consumed within 48hrs after opening the vacuum package, it is recommended that the bags be resealed.

- Material is available in both long and short grain. The grain direction is indicated on the label with an arrow.

Designing And Inner Layer Process

- Please be careful when single ply of 1080, 1086, 1078 or 106 prepreg is designed to the dielectric layer.

- Dimension stability is the same as Standard FR4 material.

- Please check with your oxide vendor to make sure that our material is suitable with your oxide process. We recommend to control the peel strength with brown oxide copper over 2 Lb/in.

- For unclad or single sided laminates to be used in multilayer, please brush unclad sides before use.

Prepreg Availability

E-Glass styles: 7628, 1506, 2113, 2116, 1080, 1078, 106, 1067, 1037, 1027, 1017 etc.Prepreg Availability

| PP Type | Resin Content | Press Thickness (mil) | DK | DF | Remark | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 1GHz | @ 2GHz | @ 5GHz | @ 10GHz | @ 1GHz | @ 2GHz | @ 5GHz | @ 10GHz | ||||

| 7628 | 49% | 8.20 | 4.23 | 4.18 | 4.13 | 4.08 | 0.012 | 0.013 | 0.013 | 0.014 | Standard |

| 7628 | 45% | 7.60 | 4.35 | 4.30 | 4.25 | 4.25 | 0.012 | 0.013 | 0.013 | 0.014 | Standard |

| 1506 | 52% | 7.20 | 4.15 | 4.10 | 4.05 | 4.05 | 0.013 | 0.014 | 0.014 | 0.015 | Standard |

| 2116 | 58% | 5.20 | 3.98 | 3.93 | 3.88 | 3.88 | 0.013 | 0.014 | 0.014 | 0.015 | Standard |

| 2116 | 54% | 4.80 | 4.10 | 4.05 | 4.00 | 4.00 | 0.013 | 0.014 | 0.014 | 0.015 | Standard |

| 2116 | 52% | 4.50 | 4.15 | 4.10 | 4.05 | 4.05 | 0.013 | 0.014 | 0.014 | 0.015 | Standard |

| 2116 | 50% | 4.30 | 4.20 | 4.15 | 4.10 | 4.10 | 0.012 | 0.014 | 0.014 | 0.015 | Non-Standard |

| 2113 | 57% | 4.10 | 4.00 | 3.95 | 3.90 | 3.90 | 0.013 | 0.014 | 0.014 | 0.015 | Standard |

| 1080 | 68% | 3.30 | 3.80 | 3.73 | 3.68 | 3.68 | 0.014 | 0.015 | 0.015 | 0.016 | Standard |

| 1080 | 66% | 3.10 | 3.83 | 3.76 | 3.70 | 3.70 | 0.014 | 0.015 | 0.015 | 0.016 | Standard |

| 1080 | 63% | 2.90 | 3.88 | 3.78 | 3.73 | 3.73 | 0.014 | 0.015 | 0.015 | 0.016 | Non-Standard |

| 1078 | 68% | 3.50 | 3.80 | 3.73 | 3.68 | 3.68 | 0.014 | 0.015 | 0.015 | 0.016 | Non-Standard |

| 1078 | 65% | 3.10 | 3.83 | 3.76 | 3.70 | 3.70 | 0.014 | 0.015 | 0.015 | 0.016 | Standard |

| 1067 | 73% | 2.70 | 3.72 | 3.62 | 3.56 | 3.56 | 0.015 | 0.016 | 0.016 | 0.017 | Standard |

| 1067 | 75% | 2.90 | 3.70 | 3.60 | 3.54 | 3.54 | 0.015 | 0.016 | 0.016 | 0.017 | Non-Standard |

| 1067 | 73% | 2.70 | 3.72 | 3.62 | 3.56 | 3.56 | 0.015 | 0.016 | 0.016 | 0.017 | Standard |

| 106 | 75% | 2.30 | 3.70 | 3.60 | 3.54 | 3.54 | 0.015 | 0.016 | 0.016 | 0.017 | Standard |

| 106 | 73% | 2.10 | 3.72 | 3.62 | 3.56 | 3.56 | 0.015 | 0.016 | 0.016 | 0.017 | Non-Standard |

| 1037 | 75% | 2.20 | 3.70 | 3.60 | 3.54 | 3.54 | 0.015 | 0.016 | 0.016 | 0.017 | Non-Standard |

| 1037 | 73% | 2.00 | 3.72 | 3.62 | 3.56 | 3.56 | 0.015 | 0.016 | 0.016 | 0.017 | Non-Standard |

| 1037 | 71% | 1.90 | 3.77 | 3.67 | 3.63 | 3.63 | 0.015 | 0.016 | 0.016 | 0.017 | Standard |

| 1027 | 76% | 1.90 | 3.68 | 3.58 | 3.52 | 3.52 | 0.016 | 0.017 | 0.017 | 0.018 | Non-Standard |

| 1027 | 72% | 1.60 | 3.73 | 3.63 | 3.58 | 3.58 | 0.015 | 0.016 | 0.016 | 0.017 | Standard |

| 1017 | 73% | 1.30 | 3.72 | 3.62 | 3.56 | 3.56 | 0.015 | 0.016 | 0.016 | 0.017 | Standard |

① Press thickness test condition---Prepreg lamination size 18”*24”, Copper Foil---1oz/1oz, Flow---about 5%; ② Make laminated prepreg to micro-section and measure the thickness with microscope; this thickness is used for resistance design calculation. ③ The thickness measured with micrometer is 0.2~0.4 mil larger than that measured with micro-section; and mainly used for total thickness design calculation.

Laminate Availablity

Thickness: 0.0015” (0.038mm) to 0.200” (5mm), available in sheet or panel form Copper Foil: 1/4 to 12oz, HTE or RTF or DST Note: For cores ≤0.005”, it is recommended to use the reverse treated copper due to the low profile. The peel strength for RT foil is 1-2lb/in (0.35Kg/m) less than Standard foil.Laminate Availability

| Core thk. (Inches) | Stack-up | Resin Content | DK | DF | Remark | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| @ 1GHz | @ 2GHz | @ 5GHz | @ 10GHz | @ 1GHz | @ 2GHz | @ 5GHz | @ 10GHz | ||||

| 0.0015 | 1-1027 | 70% | 3.77 | 3.67 | 3.60 | 3.60 | 0.015 | 0.016 | 0.016 | 0.017 | Standard |

| 0.002 | 1-1037 | 72% | 3.73 | 3.63 | 3.58 | 3.58 | 0.015 | 0.016 | 0.016 | 0.017 | Non-standard |

| 0.002 | 1-106 | 72% | 3.73 | 3.63 | 3.58 | 3.58 | 0.015 | 0.016 | 0.016 | 0.017 | Standard |

| 0.003 | 1-1080 | 66% | 3.83 | 3.73 | 3.68 | 3.68 | 0.014 | 0.015 | 0.015 | 0.016 | Standard |

| 0.004 | 1-2116 | 46% | 4.35 | 4.30 | 4.25 | 4.20 | 0.013 | 0.014 | 0.014 | 0.015 | Standard |

| 0.004 | 2-106 | 72% | 3.73 | 3.63 | 3.58 | 3.58 | 0.015 | 0.016 | 0.016 | 0.017 | 2ply |

| 0.005 | 1-2116 | 55% | 4.05 | 4.00 | 3.95 | 3.95 | 0.013 | 0.014 | 0.014 | 0.015 | Standard |

| 0.006 | 1-1506 | 45% | 4.35 | 4.30 | 4.25 | 4.20 | 0.012 | 0.013 | 0.013 | 0.014 | Standard |

| 0.007 | 1-7628 | 41% | 4.50 | 4.45 | 4.40 | 4.40 | 0.012 | 0.013 | 0.013 | 0.014 | Standard |

| 0.008 | 1-7628 | 46% | 4.35 | 4.30 | 4.25 | 4.25 | 0.012 | 0.013 | 0.013 | 0.014 | Standard |

| 0.008 | 2-2116 | 46% | 4.35 | 4.30 | 4.25 | 4.25 | 0.012 | 0.013 | 0.013 | 0.014 | 2ply |

| 0.010 | 2-2116 | 55% | 4.05 | 4.00 | 3.95 | 3.95 | 0.013 | 0.014 | 0.014 | 0.015 | Standard |

| 0.012 | 2-1506 | 45% | 4.35 | 4.30 | 4.25 | 4.25 | 0.012 | 0.013 | 0.013 | 0.014 | Standard |

| 0.014 | 2-7628 | 41% | 4.50 | 4.45 | 4.40 | 4.40 | 0.012 | 0.013 | 0.013 | 0.014 | Standard |

| 0.016 | 2-7628 | 46% | 4.35 | 4.30 | 4.25 | 4.25 | 0.012 | 0.013 | 0.013 | 0.014 | Standard |

| 0.028 | 4-7628 | 41% | 4.50 | 4.45 | 4.40 | 4.40 | 0.012 | 0.013 | 0.013 | 0.014 | Standard |

| 0.036 | 5-7628 | 43% | 4.40 | 4.35 | 4.30 | 4.30 | 0.012 | 0.013 | 0.013 | 0.014 | Standard |

| 0.045 | 6-7628 | 46% | 4.35 | 4.30 | 4.25 | 4.25 | 0.012 | 0.013 | 0.013 | 0.014 | Standard |

| 0.049 | 7-7628 | 41% | 4.50 | 4.45 | 4.40 | 4.40 | 0.012 | 0.013 | 0.013 | 0.014 | Standard |

| 0.059 | 8-7628 | 44% | 4.40 | 4.35 | 4.30 | 4.30 | 0.012 | 0.013 | 0.013 | 0.014 | Standard |

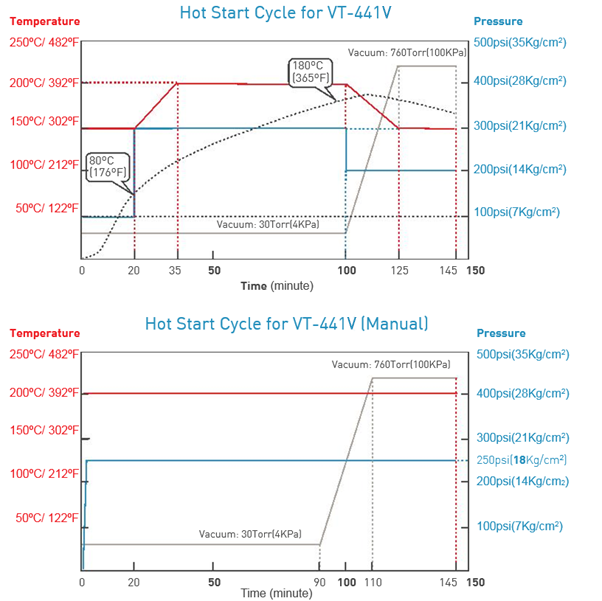

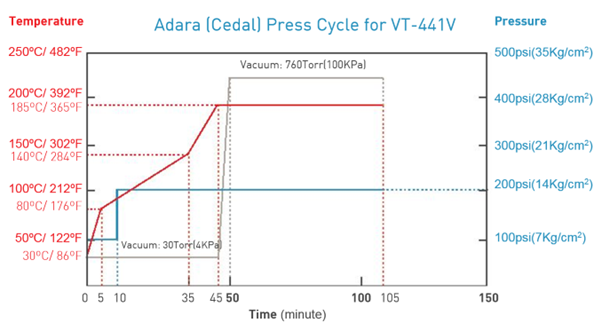

Press Condition

1. Heating rate(Rise of Rate) of material [Material Temperature]

Programmable Press: 1.5-3.0℃/min (3~5℉/min). Manual Press:3~6℃ /min (5~10℉/min)

2. Curing Temperature & Time: >50min at more than 180℃ (356℉)[Material Temperature]

3. Full Pressure : ≥250-300psi

4. Vacuuming should be continued until over 140℃ (284℉) [Material Temperature]

5. Cold Press condition: Keep Plate @ Room Temperature by water, Pressure: 100psi, Keep Time: 60minutes